If you run a machine shop or do machine work, you probably specialize in specific materials. For example, your equipment may be set up to machine plastics, or you might concentrate on iron or steel parts. Perhaps you already handle steel and aluminum, and you’d like to add stainless steel machining to your services. Should you take on this new work or hire an outside shop for the job? Here are some pros and cons of this decision to consider.

Pros of Doing Your Own Work

You have complete control over all the processes and machinery. You can use your machinery and employees in any way you see fit. This is an important thing to consider. However, there are some downsides.

Cons

If you decide to do your own work, you may have to hire more help. Every time you add an employee to your payroll you increase your worker compensation insurance and medical insurance costs. You’ll also have more people to supervise, and your weekly payroll will increase (along with your operating costs).

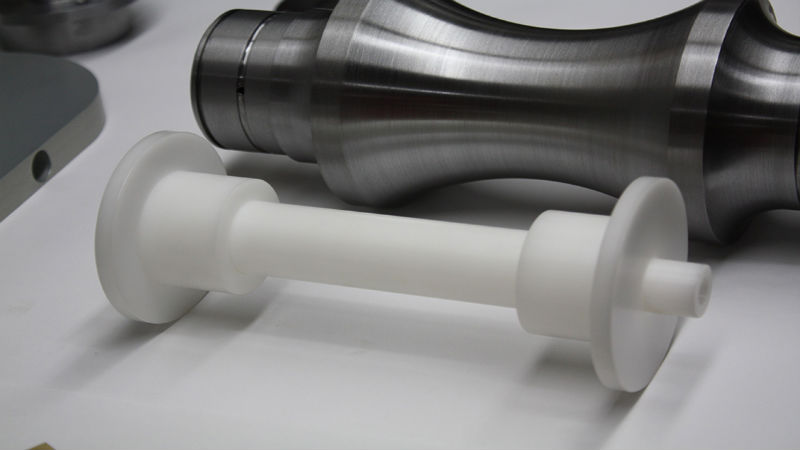

Stainless steel machining is not difficult, but it can be problematic if you don’t use the right methods, have the right tools, and know what you are doing. You may need to invest in more equipment, sharper tools, or machines that can handle the job of working with stainless steel.

Hiring a Trusted Stainless Steel Machining Service

All of the downsides of doing your own work can be avoided when you use an experienced shop for the job. In fact, some shops offer complete contract manufacturing services, and they can handle your projects from start to finish. You can cut your operating costs substantially and add new services at the same time. This is a good way to increase your customer base and profits.