The aerospace industry encompasses a lot of businesses today and the machine shop who can serve these needs should have no trouble staying in business in the future. If you would like to be a part of this industry, you have two basic options. You can open up your own aerospace machine shop or hire the services of a reputable company, capable of delivering what you need. Let’s explore both of these options to see which is best for you.

What Does It Take to Serve the Airline or Space Industry?

Location is important and many businesses choose to be near their customers. For example, Seattle and Los Angeles are two very good choices and you could move your operation to the West Coast, but this could be far more expensive than you can imagine. In fact, most people would consider this kind of move to be a “pipe dream”. So, changing locations may not be a viable option or even possible at this point.

Certifications

You should have specific certifications if you are serious about opening up an aerospace machine shop. For example, it is important to be AS9100 certified. This is a quality control certification designed specifically for the aerospace industry. You must have an approved quality control system in place and the shop must prove it is focused on customer needs, leadership, involvement of people and many other things.

Becoming certified can involve a lot of expenses including employee training programs. In addition, the quality control system is inspected and audited by ISO officials. Every three years you must go through a detailed inspection and audit before your certification can be renewed. All of the expenses and time involved can be avoided when you hire the services of a company who is properly certified.

Special Equipment

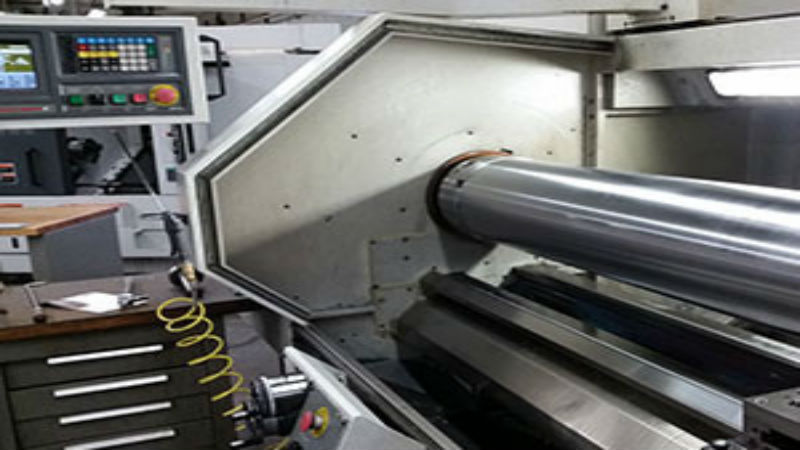

You may need to buy special CNC machining equipment and it may not be used all the time, unless all of your customers are in the aerospace industry. In addition, special machining methods require a great deal of skill and it may be necessary to invest in additional skilled labor. Experienced machinists command high wages and good job benefit packages, and this can cut into your operating expenses considerably.

Finding Enough Customers

In the beginning, your new aerospace machine shop may have difficulty establishing a customer base. In fact, it could take a very long time to recoup your startup investment. There are many reasons to consider outsourcing this kind of work, at least until you are established in the business.