While bronze is not an alloy that is used in large quantities for most types of applications, bronze parts and components are used in a variety of different types of machines, equipment, and devices.

A Bit About Bronze

Bronze itself is made up of mostly copper and tin as well as the addition of different metals such as manganese, nickel, zinc or aluminum. It can also include phosphorus and silicon as well as arsenic, which are not true metals but are considered to be metalloids. The various metals or non-metals used to create the specific grade of bronze will change the characteristics of the metal for increased performance in specific applications.

Bronze machining of components in the electrical, telecommunications, mining, processing and refining industries is common, as is the specific use of bronze parts in hydraulic systems as well as bushings and bearings. Bronze is uniquely resistant to corrosion through exposure to water and also provides a friction reducing surface, which is why it is a popular metal for bearings and bushings.

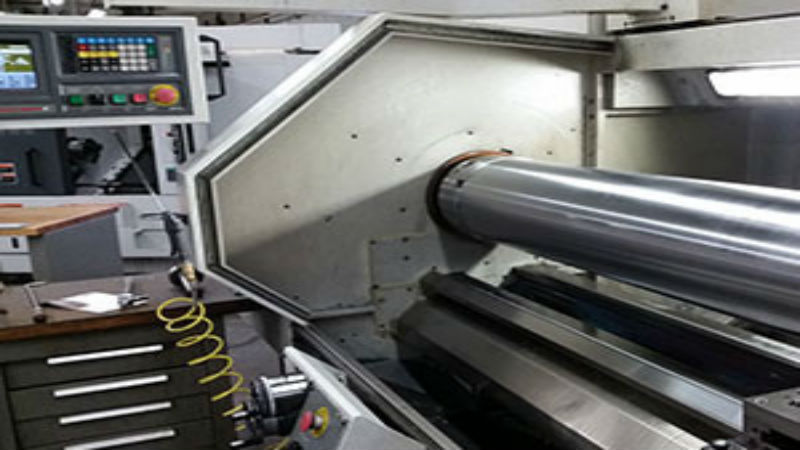

Each type of bronze requires different considerations when working with the alloy. Different types of bronze are easier to work with than others, so when considering bronze machining services, it is important to choose a company with experience and expertise in working with the alloy grade required for your part or components.

Requirements of the Order

There are some companies offering bronze machining that will have minimum production run requirements. Other companies may provide prototyping services as well as small orders without any additional cost for minimum volume requirements for the customer.

It is important also to verify that any company offering custom machining has the full capacity to complete all aspects of the job in-house. Some machining companies will sub contract out different parts of the project, which can lead to delays in production as well as inconsistencies in the quality of machining work completed.